Do You Need an EPS Styrofoam Densifier To Process The Material For Profit?

Call 908-566-7256 For A Free Site Evaluation Survey!

Do You Currently Have Densified EPS Styrofoam That You Are Looking To Sell And Need Pricing?

Call 908-566-7256 For A Top Of The Market Price Quote!

According to GBI Research, global demand for both polystyrene and EPS increased to 14.9 million tons in 2010 from 13 million tons in 2000, swelling to 23.5 million tons in 2020. Some of the product is sourced from the Middle East.

Increased EPS production = intensified recycling efforts. (More EPS results in more polystyrene waste, which, if disposed of in landfills takes up significant space. Of equal concern, being non-compostable and essentially non-biodegradable, it would take centuries for EPS to decompose.

Highly effective polystyrene recycling technology exists; in fact, recyclers have been producing goods from recycled polystyrene for years.

One of the reasons why polystyrene waste recycling is not fully available across the country, even among recyclers, is the high cost associated with transporting the waste because of its volume to weight ratio.

FACT: A truckload of EPS foam contains very little polystyrene (95-98% of its content is air).

Volume reduction equipment offered in the market include balers, and densifiers, defined as follows:

Thermoplastics, like compressed polystyrene, can be melted and remolded into different plastic products, and recyclers are finding myriad innovative ways to do just that. It has been fashioned into CD cases, coat hangers, picture frames, toys, and office supplies such as pens, stapler bodies, and rulers.

Recycled EPS is also utilized to manufacture wood-alternative products like interior decorative moldings–comparable to softwood, but have the advantage of being both water- and mold-resistant, and impervious to rotting and decay.

Your Foam Waste processed and becomes Profits!!

The RecycleTech XT300D EPS foam densifier Specialized in furniture and appliance foam, foam cups and plates. Customers can reduce their total waste hauling cost by as much as 80%. Our customers are not only saving thousands of dollars daily, but also generating income from their styrofoam EPS wastel StyroSolutions will buy back 100% of your processed EPS

Why XT-300D

Fast and easy loading

Moveable — On castors!

Compact and Cost effective

Gfeat output volume per operation cost ratio.

Applications

Foam cups and plates.

Furniture foam

Appliance foam

Packing pieces.

XT-300D Specifications

a. Densifies EPS B. Machine Dimensions (includes feeding hopper): 67 (L) x 42 (W) x 60 (H) c. Weight: 2,645 lbs d. Feed Opening (Hopper) Dimensions: 32 (L) x 26 (W) e. EPS Density: 150~200 lbs / ft3 f. Power Requirements: 220V 3Phase 75 Amps g. Capable of processing approximately 250 lbs of loose foam per hour

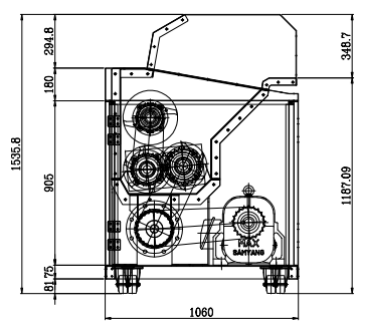

| Capacity | 50-80 kg/hr |

| Main Motor | 15 Kw (480v*3P) |

| Crusher Motor | Power : 5.5 KW (480*3P) Type : |

| Screw (kW/h) | Size : 235 x L1400 (mm)) pitch : 180mm |

| Bale Size | 250w*250H*L |

| Capacity (lb/h) | Up to 200 |

| Hopper size (WxL) | 724 x 420 |

| Machine dimension (W×L×H) | 2963 x 1769 x 1809 |

| Electrical usage (kW/h) | 11 |

Turn your Foam Waste into an Income Source… and say good-bye to your foam waste hauling bill.

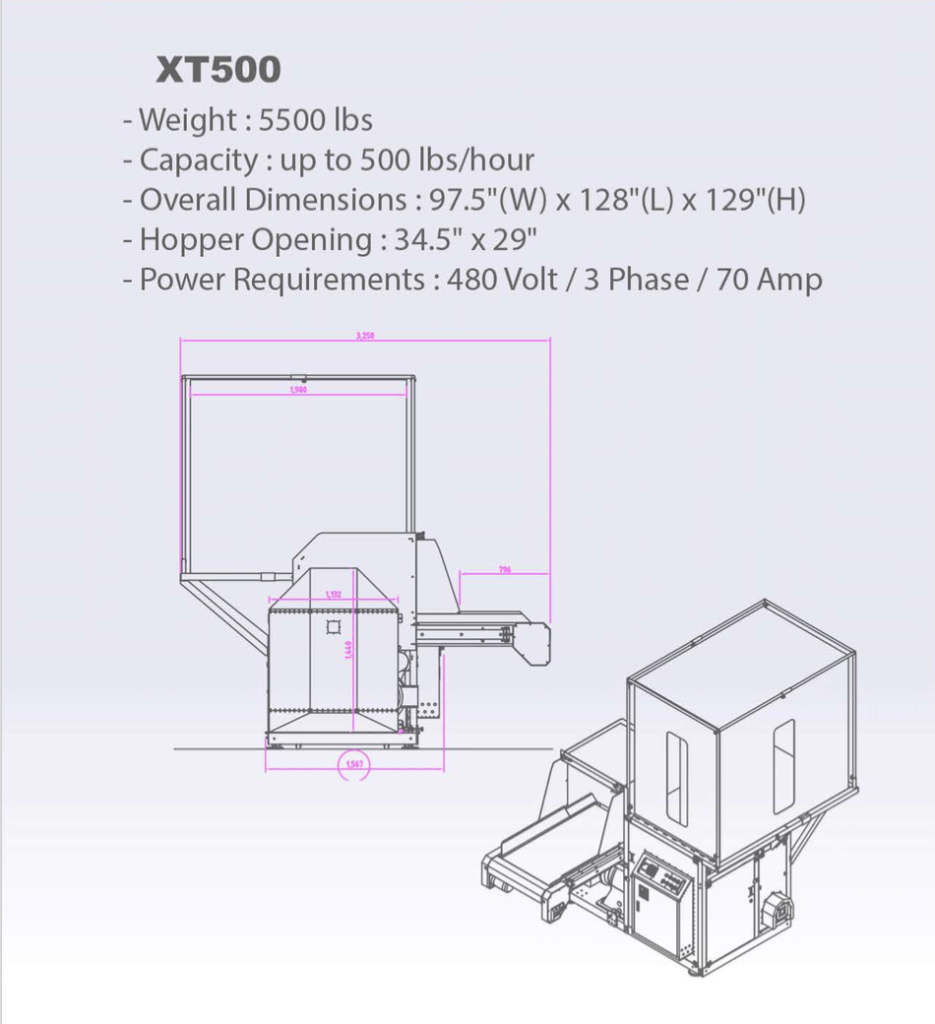

The XT500 EPS foam densifier by RecycleTech can reduce your total waste hauling cost by up to 80%. Our customers are not only saving thousands of dollars daily, but also generating income from their EPS foam waste! StyroSolutions will buy back 100% of your processed EPS.

Why XT500

Fast, easy loading with conveyor system. Cost effective with a great output volume per operation cost ratio.

Applications

Mid to large-sized distribution centers/manufacturers. Mid to large-sized electronic recycle & repair centers.

XT 500 Specifications

Weight: 5,500 Ibs. Capacity: 500 Ibs/hour.

Overall Dimensions: 97.5"(W) x 186"(L) x 129"(H).

Hopper Opening: 34.5" x 29°

Power Requirements: 480 Volt / 3 Phase / 70 Amp

Turn your Foam Waste into an Income Source… and say good-bye to your foam waste hauling bill.

The XT400 EPS foam densifier by RecycleTech can reduce your total waste hauling cost by up to 80%. Our customers are not only saving thousands of dollars daily, but also generating income from their EPS foam waste! StyroSolutions will buy back 100% of your processed EPS.

Why XT400

Fast, easy loading with conveyor system. Cost effective with a great output volume per operation cost ratio.

Applications

Mid to large-sized distribution centers/manufacturers.

Mid to large-sized electronic recycle & repair centers.

XT 400 Specifications

Weight: 5,500 lbs.

Capacity: 400 lbs/hour.

Overall Dimensions: 97.5″(W) x 128″(L) x 129″(H).

Hopper Opening: 34.5″ x 29″.

Power Requirements:

480 Volt/3 Phase/70 Amp. 220V model available

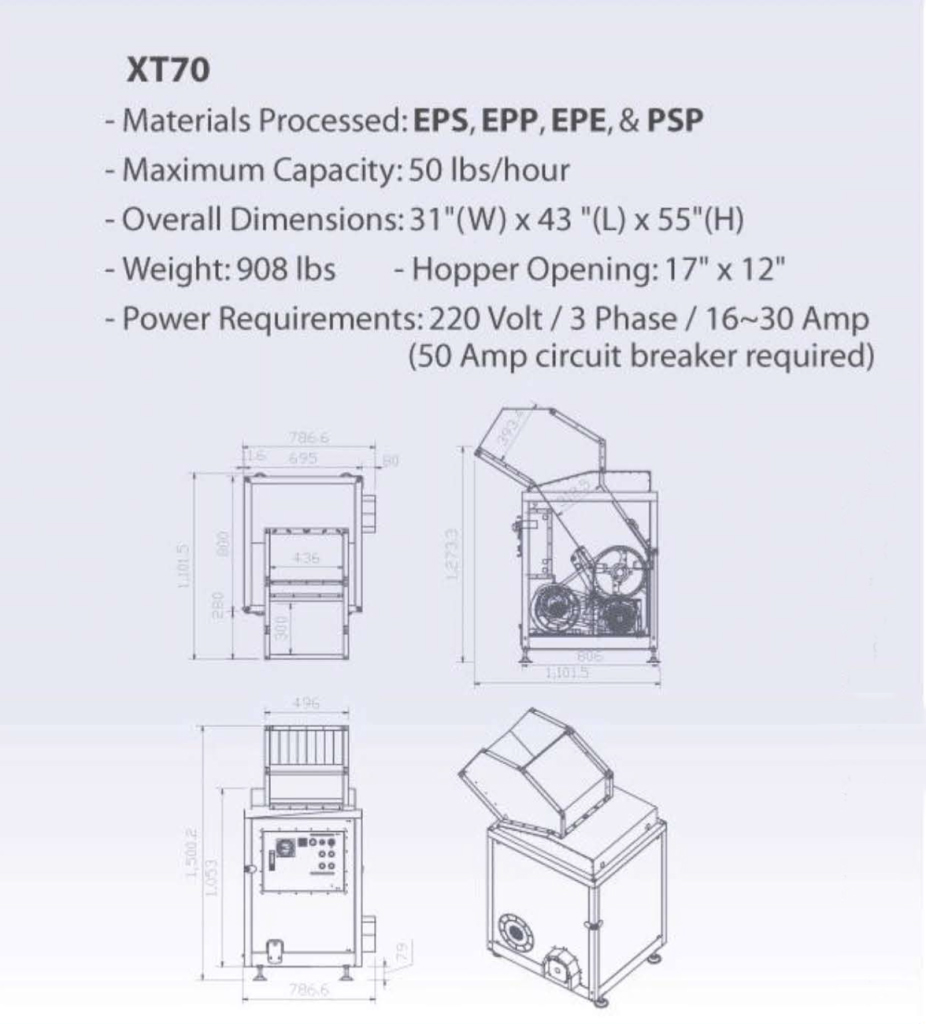

The XT70 is the perfect densifier for small businesses to process their Styrofoam waste. Our most compact and versatile foam densifier, this machine will process up to 50 lbs of expanded polystyrene waste (EPS) per hour. Businesses looking for a fast and quick solution to their EPS waste will find that the XT70 is capable of being transported and installed with ease due to its small footprint.

Why XT70

Processes multiple foam materials including EPS food containers and EPE packaging blocks. Compact size fits in smaller spaces. Competitively priced/cost effective. Easy to move around

Applications

Schools, Hospitals, and organizations with cafeterias. Small-sized warehouses/retail stores. Grocery markets

*Food containers need to be free of food waste

XT70 Specifications

Materials: EPS, EPP, EPE, & PSP

Weight: 908 Ibs.

Max. Capacity: 50 Ibs/hour.

Overall Dimensions: 31"(W) x 43 “(L) x 55"(H)

Hopper Opening: 17" x 12"

Power Requirements: 220 Volt / 3 Phase / 16~30 Amp

(50 Amp circuit breaker required)

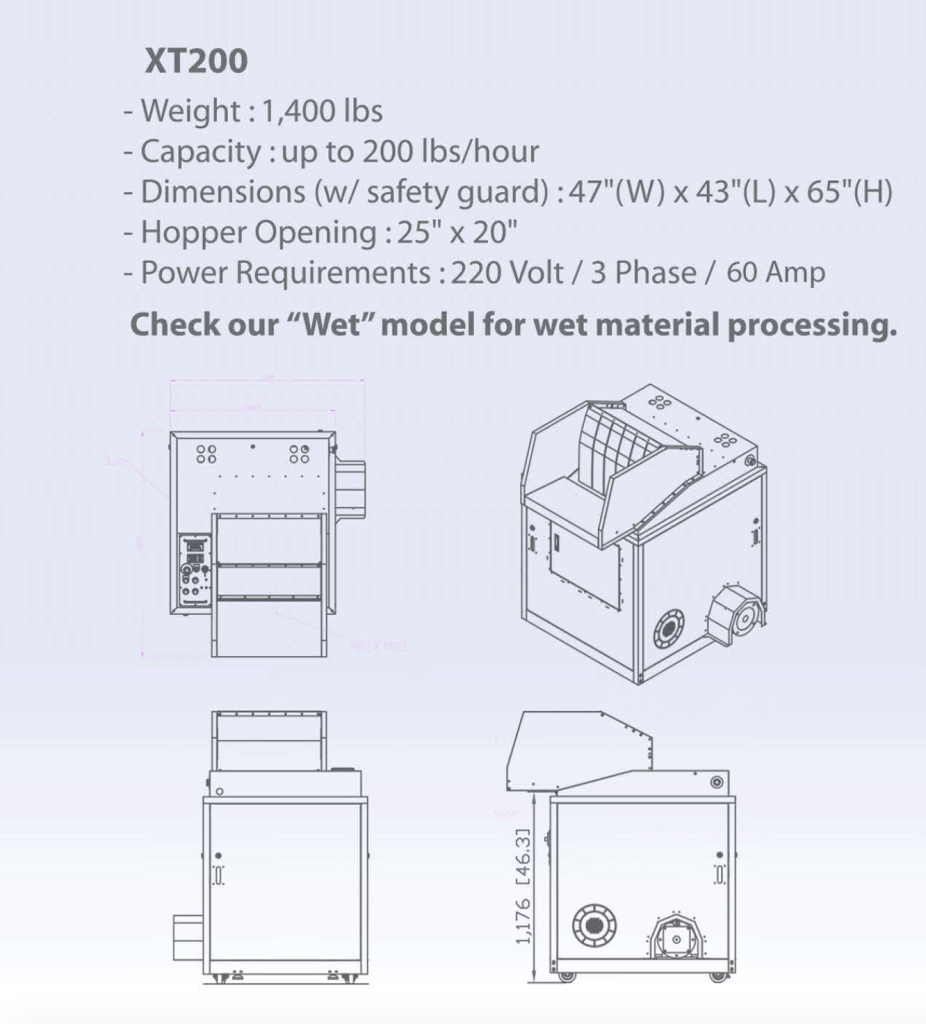

Our most popular Styrofoam recycling machine, the XT200 is right in the middle of our product line-up in terms of efficiency and processing lbs per hour. Designed with quality in mind, the XT200 processes 200 lbs of Styrofoam per hour. Mid-sized businesses with a constant stream of Styrofoam waste will find that this recycling solution is the perfect means to turn their EPS into a valuable resource.

Why XT200

Competitively priced/cost effective. Convenient and safe for public use. Easy to move around. Easy to maintain.

Applications

Small to mid-sized warehouses/retail stores. Small to mid-sized electronic recycle & repair centers. Schools or Government offices.

XT200 Specifications

Weight: 1,400 lbs. Capacity: 200 lbs/hour. Overall Dimensions (w/ safety guard): 47″(W) x 43″(L) x 65 “(H). Hopper Opening: 25″ x 20″. Power Requirements: 220 Volt/3 Phase/60 Amp